-40%

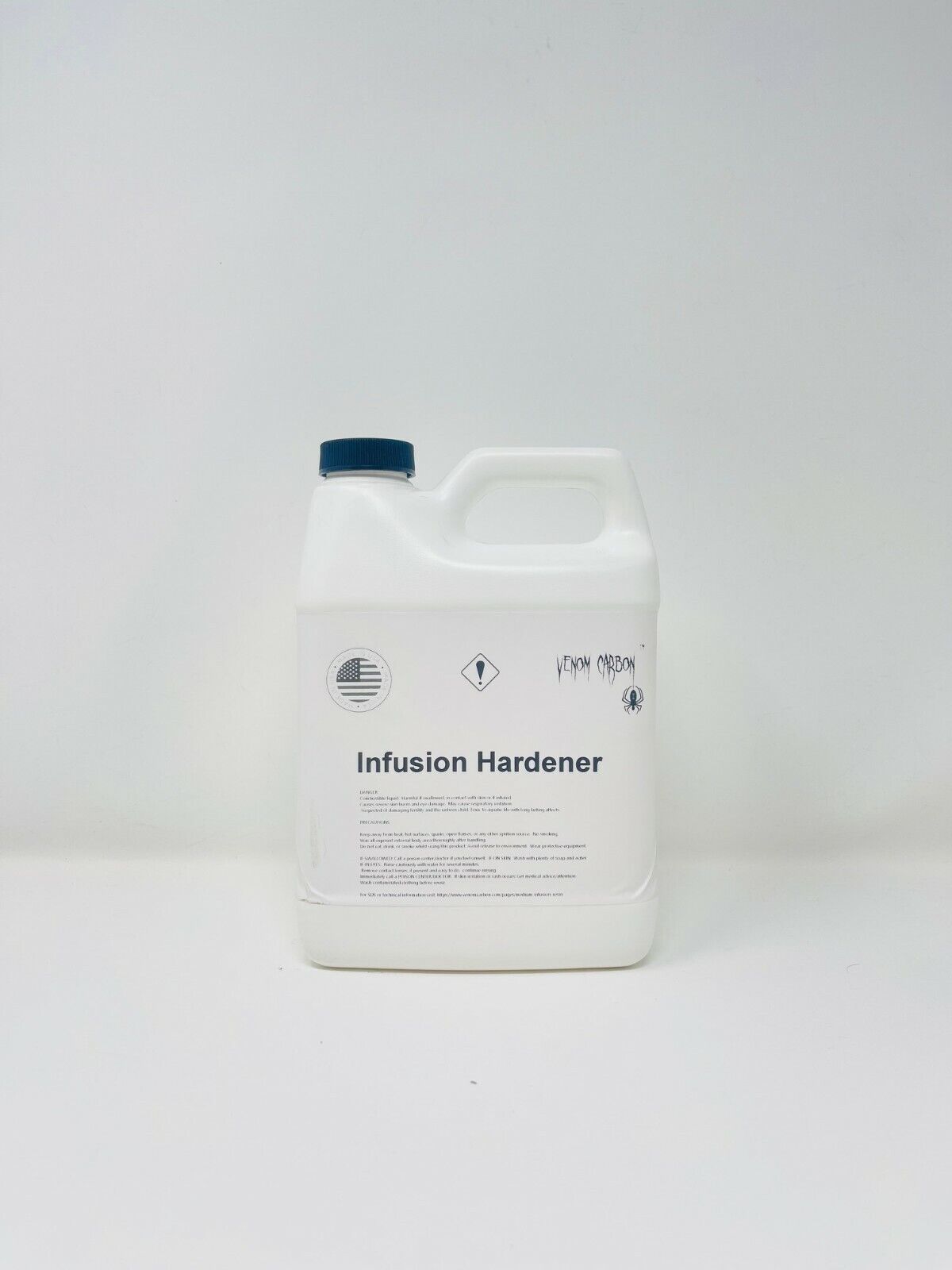

Vacuum Infusion Resin Medium Cure ( 1 gallon kit )

$ 69.95

- Description

- Size Guide

Description

MEDIUM INFUSION EPOXY – A-298/B-225DESCRIPTION

Medium Infusion Epoxy is a two-component, very low viscosity system developed specifically for use in resin infusion and VARTM processes. Medium Infusion Epoxy was formulated to provide for rapid saturation of carbon fiber laminate, fiberglass, and Kevlar. Processability parameters are enhanced due to Medium Infusion Epoxy’s low mixed viscosity and wet-out potential. This system is not designed to be used in open mold applications.

HANDLING PROPERTIES

RESIN VISCOSITY, cP 1,044 ASTM D 2196

RESIN DENSITY, lb./gal 9.49 ASTM D 792

HARDENER VISCOSITY, cP 39 ASTM D 2196

HARDENER DENSITY, lb./gal 7.78 ASTM D 792

COLOR Clear

DENSITY, lb./gal 9.02 ASTM D 792

MIX RATIO, pbv (pbw) 3/1 (3.65/1)

MIXED VISCOSITY, cP 291 ASTM D 2196

GEL TIME (200g), min 160 ASTM D 2471

WORKING TIME*, min 120

*The working time varies according to the temperature of the air, the epoxy and the surface to which it is applied.

Note: Above viscosities/densities measured @ 77°F.

PHYSICAL PROPERTIES

TENSILE STRENGTH, psi 10,300 ASTM D 638

TENSILE MODULUS, psi 294,000 ASTM D 638

ELONGATION @ BREAK, % 3.16 ASTM D 638

COMPRESSIVE STRENGTH, psi 13,700 ASTM D 695

COMPRESSIVE MODULUS, psi 263,000 ASTM D 695

FLEXURAL STRENGTH, psi 17,300 ASTM D 790

FLEXURAL MODULUS, psi 1,063,000 ASTM D 790

HARDNESS, Shore D 88D ASTM D 2240

Cure Cycle: 24hours @ Room Temperature + 8 hours @ 180°F. Test specimens for above were neat epoxy (without fiber reinforcement).

THERMAL PROPERTIES

Tg DMA Peak Tan Delta, °F (°C)* 232 (111) ASTM 1640

Tg DMA Onset Storage Modulus, °F (°C)* 94 (90) ASTM 1640

Heat Deflection Temperature, °F °(C) 195 (90.5) ASTM 648

Tg DSC Ultimate 207 (97.4) ASTM E 1356

*1 Hz, 3°C per minute.

Cure Cycle: 24 hours @ Room Temperature + 4 hours @ 250°F.

STORAGE INFORMATION

The storage temperature of Medium Infusion Epoxy will greatly affect the ease of mixing, application and, curing time. For best results, Medium Infusion Epoxy should be stored at (60-80 °F or 16-27 °C) for

at least 24 hours before use.

MIXING INFORMATION

Mix RESIN WITH (hardener) for 3 minutes using a Jiffy Mixer and a slow speed drill. Mix at slow speed (less than 500 rpm) to avoid air entrainment. When adding part B to part A, be sure to scrape the sides of the hardener (part B) container in order to remove all of the hardener. This is essential to maintain proper mix ratio. DO NOT mix more material than can be used within the stated working time. REMEMBER - you will have less working time at higher temperatures.

CRYSTALLIZATION INFORMATION

Crystallization of epoxy resin is not an uncommon occurrence; in some cases, it is simply a reflection of the high-performance nature of the material. Under the perfect conditions, usually extreme temperature change, any epoxy resin can crystalize. The crystallization may present itself as the resin becoming cloudy all the way to the resin turning to a solid.

Follow the following steps to restore a crystallized epoxy resin to its normal state:

1)

Place resin container in warm water until the resin reaches approximately 120-degrees Fahrenheit. (An easy way to achieve this with normal household products is a crockpot)

2)

Keep epoxy resin at this temperature for several hours. Mixing may be needed while warm to dissolve all crystals.

3)

Allow the epoxy resin to cool back down to room temperature before use. The resin being warm can drastically change working times.

4)

Feel free to use this epoxy resin just as you normally would.

SAFETY PRECAUTIONS

Avoid breathing of vapors. Forced local exhaust is recommended to effectively minimize exposure. NIOSH approved, organic vapor respirators and forced exhaust are recommended in confined areas, or when conditions (such as heated polymers, sanding) may cause high vapor concentrations.

DO NOT WELD ON, BURN OR TORCH ON OR NEAR, ANY EPOXY MATERIAL. HAZARDOUS VAPOR IS RELEASED WHEN AN EPOXY IS BURNED.

WARRANTY AND DISCLAIMER

ICT/Venom Carbon gives no warranty, express or implied, and all products are sold upon condition that purchasers will make their own tests to determine the quality and suitability of the product ICT/Venom Carbon shall be in no way responsible for the proper use and service of the product. The information given in this publication is considered to be accurate and reliable and is provided as a service only. Physical properties shown are typical. Actual properties are dependent on curing conditions and degree of cure. Any information or suggestions given are without warranty of any kind and purchasers are solely responsible for any loss arising from the use of such information or suggestions. No information or suggestions given by us shall be deemed to be a recommendation to use any product in conflict with any existing patent rights.