-40%

Silver Conductive Epoxy Cold Solder, PCB, Electronic Repair Solution 906, 2.5g

$ 7.91

- Description

- Size Guide

Description

Technical Product BulletinSILVER EPOXY ELECTRICAL CONDUCTOR

NOT for Defroster and/or Gridline Repair. Windshield will shatter. Use Atom Adhesives Defroster Repair product.*****

PRODUCT DESCRIPTION:

AA-DUCT 906

represents the newest technology since the introduction of electrically conductive silver compounds. This

unique formulation is

based on a silver coated ceramic that results

in lower material costs without adversely sacrificing

the properties obtained with a pure silver

formulation. This concept opens the door to a wide

range of applications

previously prohibited

by the much higher cost of conventional silver

conductive.

AA-DUCT 906

cures at room temperature or can be accelerated with mild heat to form a tenacious bond between similar

and dissimilar substrates

such as aluminum, copper, magnesium,

steel, bronze nickel, ceramic, glass, phenolic, and G-10

epoxy glass boards.

AA-DUCT 906

, because of its excellent continuity, has been used extensively in such diversified

applications as, microwave EMI and RFI

shielding, in the assembly or repair of printed

circuit boards, wave guides,

electronic modules, flat cable, high frequency shields, connections,

and circuitry and as a cold solder. This unique

formulation offers ease in handling due to

its creamy consistency and versatile application by

hand, automatic dispenser,

silk-screening, transfer

or stamping techniques.

PRODUCT PROPERTIES:

Appearance

Silver

Cure Type

Heat cure or Room temperature

Benefits

High strength

Perfect bond

EMI & RFI shielding

Cold Solder

Substrates

Excellent choice aluminum, copper, magnesium, steel, bronze, nickel, kovar, ceramic, glass, phenolic and G-10 epoxy glass boards.

UNCURED PROPERTIES:

Viscosity

@ 25 °C cps

Paste

Silver coated ceramic

, %

50 to 75

Pot Life

@ RT

1 Hour

Mix ratio, by weight

100:5 / Resin:Hardener

Shelf life

1 Year

CURE SCHEDULE:

15 minutes

@ 100°C

30 minutes

@ 60°C

24 hours

@ Room temperature

CURED PROPERTIES:

Volume Resistivity

< 0.0015

Hardness, Shore D

81

Compressive Strength, psi

13,600

Shrinkage Linear, in / in

0.004

Specific Gravity

, 25°C / 25°C

2.60

Tensile Strength

, psi

8,900

Compressive Strength

, psi

13,700

THERMAL PROPERTIES:

Thermal Conductivity

, btu / hr / ft2 / °F / in

90

Thermal Expansion Coefficient

, (cm / cm / °C • 10-5)

1.9

Heat Distortion

, °C

90

Operating Temperature Range,

°C

-50 to +165

GENERAL INFORMATION:

For safe handling information on this product, consult the Material Safety Data Sheet, (MSDS).

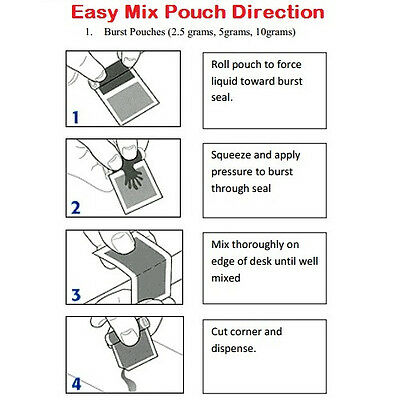

HOW TO USE:

1)

Carefully clean and dry all surfaces to be bonded.

2)

Apply

AA-DUCT 906

completely mixed adhesive to the prepared surfaces, and gently press these surfaces together.

Contact pressure is adequate for strong, reliable bonds; however, maintain contact until adhesive is completely cured.

3)

Some separation of components is common during shipping and storage. For this reason, it is recommended that the

contents of the shipping container be thoroughly mixed prior to use.

4)

Some ingredients in this formulation provided may crystallize when subjected to low temperature storage. A gentle

warming cycle of 52°C for 30 minutes prior to mixing components may be necessary. Crystallized epoxy components

do not react as well as liquid components and should be re-dissolved prior to use for best results.

AVAILABILITY:

This epoxy can be supplied in various different packages.

Froo www.froo.com | Froo Cross Sell, Free Cross Sell, Cross promote, eBay Marketing, eBay listing Apps, eBay Apps, eBay Application